Milk Processing Plant

Optimize dairy production with SS Engineers' Mini Dairy Plant, an advanced solution for organic milk processing directly at the farm. Farmers pasteurize and standardize milk fat on-site, using a batch pasteurizer and cream separator, and package fresh milk the same day to ensure quality. Milk is collected, filtered, and rapidly cooled to 4°C to minimize bacterial growth and retain freshness.

Process up to 3,000 liters daily, sourced on-site or from nearby farms. The plant offers flexibility to adjust fat content, with extracted cream convertible to butter, butter oil, or ghee, supporting diverse dairy product output.

Milk Chilling Plant

Achieve superior cleanliness with our advanced CIP System Equipment, ideal for dairy, juice, and beverage industries. Designed to sanitize pipelines and equipment without disassembly, our system uses powerful centrifugal pumps to circulate cleansing liquids, ensuring thorough and efficient cleaning.

Optimize equipment uptime and reduce labor with this AI-enhanced system, which maintains high hygiene standards seamlessly. Our CIP technology boosts operational efficiency and supports the demands of modern processing environments.

Achieve superior cleanliness with our advanced CIP System Equipment, ideal for dairy, juice, and beverage industries. Designed to sanitize pipelines and equipment without disassembly, our system uses powerful centrifugal pumps to circulate cleansing liquids, ensuring thorough and efficient cleaning.

Optimize equipment uptime and reduce labor with this AI-enhanced system, which maintains high hygiene standards seamlessly. Our CIP technology boosts operational efficiency and supports the demands of modern processing environments.

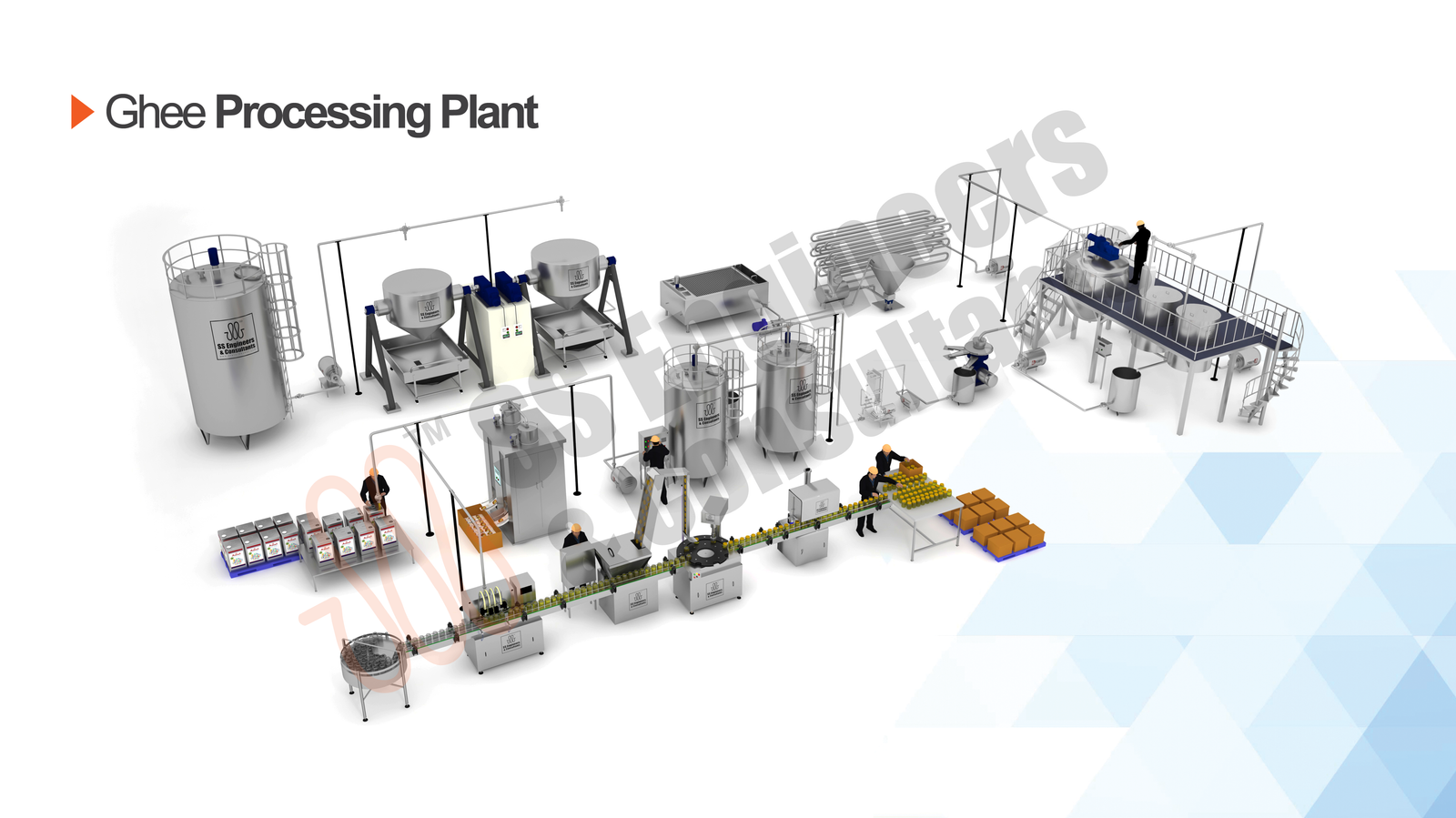

Enhance production with SS Engineers & Consultants' advanced Ghee Processing Plant, engineered for efficient extraction from milk. Our facility covers key stages such as butter melting, separation, clarification, filtration, cooling, and packaging. Equipped with balance tanks, storage tanks, kettles, pumps, and sieves, our plant is available in a range of capacities and can be tailored to meet specific client needs.

Recognized worldwide as a superfood, ghee is praised for its cooling effects, support for mental clarity, digestive benefits, and healing properties. Our innovative ghee production methods ensure high-quality, nutrient-rich ghee, preserving these essential health advantages.

Deliver top-quality solutions with SS Engineers & Consultants as we continuously engineer cutting-edge machines tailored for our clients in the culinary sector. Our industrial range empowers thousands of professional chefs, enhancing efficiency and productivity in their kitchens.

Explore our advanced offerings, including the Halwa Making Machine, Peda Making Machine, Dough Ball Machine, Rasgulla Machine, and Laddu Making Machine. Each machine is designed to streamline production processes, ensuring consistent quality and exceptional results for culinary professionals.

Revolutionize your production with SS Engineers' customized Curd Processing Plant, designed to perfectly align with your unique manufacturing needs. Available in capacities from 1 TPH to 10 TPH, our plant is built for reliability and efficiency, ensuring the production of high-quality yogurt and curd that meet today’s consumer expectations.

Leverage our advanced technology and industry expertise to enhance your manufacturing process. Our tailored configurations provide a system precisely optimized to your specifications, increasing productivity and delivering consistent results in each batch of curd and yogurt.

Explore the benefits of our Flavoured Milk Plant, where delicious, sweetened dairy beverages are crafted using milk, sugar, and natural or artificial flavors. Our ultra-high-temperature (UHT) pasteurization process extends the shelf life of flavored milk, offering a fresher, longer-lasting product compared to standard milk options.

Enhance your understanding of milk cooling systems to make informed decisions on preserving milk quality. For optimal results, cool milk to 18°C immediately after the first milking, maintain it below 13°C after subsequent milkings, and ensure it stays below 7°C until collection. Our advanced cooling solutions help you achieve precise temperature control, ensuring freshness and extending milk shelf life.

Experience the efficiency of SS Engineers & Consultants' fully automatic and semi-automatic Paneer Processing Plants, meticulously crafted from high-quality stainless steel to ensure hygienic production. Our state-of-the-art equipment guarantees optimal performance and reliability in every stage of paneer production.

Equip your facility with essential components including a Coagulation Tank, Pneumatically Operated Paneer Press, Paneer Cutting Machine, and Vacuum Packaging Machine. Each piece of machinery is designed to meet the complete requirements of your paneer plant, enhancing productivity while maintaining the highest standards of quality and hygiene.