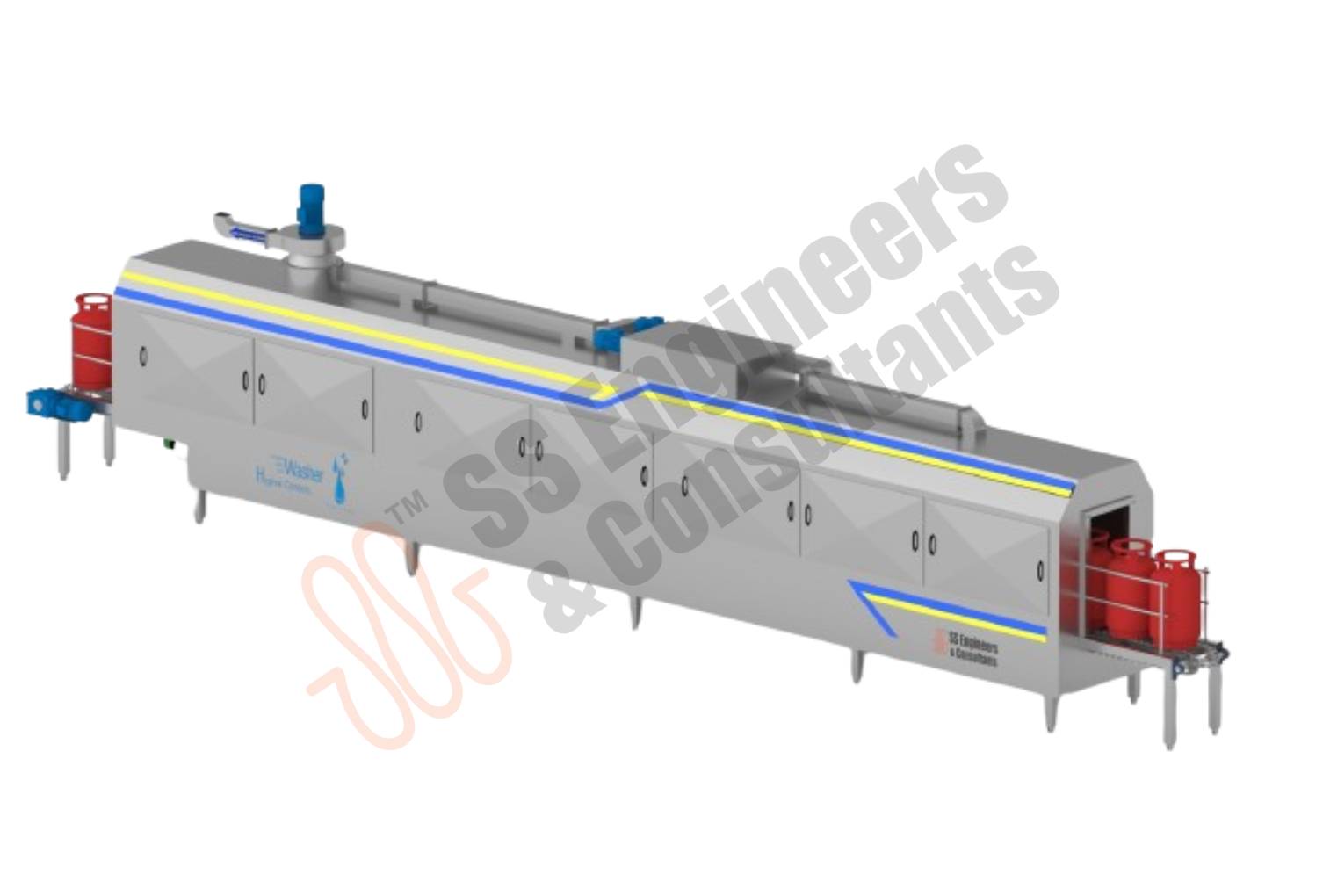

Automobile Bin Washer

Transform your operations with SS Engineers’ automated logistic systems for automobile bins washing, optimizing feeding to disposal. This advanced solution reduces manual labor, enhances efficiency, and minimizes operational costs. The system's logistics align seamlessly with the washer's capacity, creating a streamlined production line.

Boost productivity and simplify the cleaning process with SS Engineers' cutting-edge automation. Our technology ensures reliable, consistent performance, enabling a fully mechanized facility that's ready for modern manufacturing demands. Ideal for high-efficiency cleaning, this solution supports the rigorous standards required for automotive bin washing in today’s industries.

Bucket Washer

Automate your production with SS Engineers' advanced logistic systems, fully mechanized to handle every step of the washing process—from feeding to disposal—without the need for manpower. Our innovative systems synchronize seamlessly with the capacity of your washing machine, ensuring a smooth, efficient workflow for high-volume operations.

Transform facilities across India, including in Mumbai, Delhi, Chennai, and Bangalore, with fully automated solutions that enhance productivity and consistency. Whether for food processing or industrial use, SS Engineers' logistic systems provide reliable, state-of-the-art automation that meets the demands of modern manufacturing.

Revolutionize your dairy operations with SS Engineers & Consultants’ high-performance milk container washers, engineered for exceptional power and durability. Our washers provide comprehensive inside-and-out cleaning solutions, ensuring that containers are pristine and contamination-free. Explore our custom solutions today for a washer tailored to your specific needs.

Protect milk quality by preventing contamination throughout transport and processing. Our washers are designed to remove soil, foreign objects, and other contaminants from rigid and semi-rigid containers, which are essential for safely transporting milk from farms to distribution points. SS Engineers & Consultants supports the highest hygiene standards, critical for the dairy industry's success and food safety.

Elevate your seafood processing with SS Engineers & Consultants’ Crab Washer, expertly designed to remove foreign materials from crabs' surfaces. This advanced unit features a conveyor system with high-pressure nozzles that efficiently cleanse the product as it travels through the machine.

Ensure the highest hygiene standards in your operations with our innovative washing technology. The Crab Washer guarantees that your seafood is free from contaminants, promoting food safety and quality. Incorporate this reliable solution into your processing line for optimal results.

Experience the power of SS Engineers' industrial washing solutions by contacting us for a customized quotation tailored to your needs. Our advanced washers handle everything from transportation and packing crates to production line crates and utensils, ensuring thorough, efficient cleaning for any application.

Customize your material handling system to perfectly suit your operations. SS Engineers delivers flexible solutions that integrate seamlessly into your workflow, maximizing efficiency and meeting the unique demands of your industry.

Streamline your cleaning process with SS Engineers & Consultants' advanced Cylinder Washer, designed for high-efficiency mass cleaning. Capable of cleaning 800 half-cylinders per hour, it delivers a production rate of 400 cylinders per hour. The washer operates with a sequence of Hot Water Wash, Hot Water with Detergent Wash, and a Final Hot Water Rinse, with an optional Hot Air Dryer for thorough drying.

Built for large-scale cleaning operations, the Cylinder Washer ensures high performance, reliability, and hygiene standards, making it ideal for industries with heavy cleaning demands.

SS Engineers & Consultant' Industrial Dish Washer delivers superior cleaning for dishes, bowls, and kitchen utensils in commercial settings. Built with advanced international washing technology, this compact, versatile machine is designed to meet the needs of kitchens in restaurants, hotels, and industrial facilities, ensuring hygiene and efficiency.

Our Dish Washer is customizable to fit specific requirements, with options for various sizes and configurations. Ideal for cleaning everything from transportation crates to utensils, it offers a tailored, high-performance solution for all your kitchen cleaning needs. Contact SS Engineers for a customized quote and elevate your kitchen’s cleaning efficiency.

SS Engineers & Consultant' Drum Washer is designed to deliver powerful, thorough cleaning for open-top drums using a combination of static and adjustable spray nozzles. The system features an adjustable conveyor speed, allowing each drum to pass through a spray tunnel equipped with fixed nozzles or a static spray bar, ensuring consistent coverage throughout the cleaning process.

As each drum moves along the conveyor, the Drum Washer’s spray tunnel thoroughly washes and cleans the surfaces, optimizing sanitation for industrial needs. Built for efficiency, this system provides high-quality cleaning performance, making it ideal for various industrial applications.

SS Engineers & Consultants' Egg Tray Washer is designed to thoroughly wash and sanitize commercial egg trays, ensuring superior cleanliness in the egg processing industry. Built to handle heavily soiled trays without sticking, this machine meets specific customer requirements for improved productivity and streamlined operations.

Certified to eliminate even the toughest bacteria, the Egg Tray Washer achieves hygiene standards on par with those in pharmaceutical and hospital settings, making it an ideal choice for high-demand, hygiene-focused environments.

SS Engineers offers a fully automated Ice Cream Crate Washer with advanced logistics systems, handling the entire process from crate loading to disposal without manual intervention. Designed for maximum efficiency, this system provides thorough, high-speed cleaning that aligns with your production line’s capacity.

With adjustable speed controls, the Ice Cream Crate Washer ensures consistent sanitation, supporting high-volume operations effortlessly. This optimized, mechanized solution keeps crate washing streamlined and reliable, minimizing labor and maximizing productivity.

SS Engineers introduces the Incline Crate Washer - Double Track, engineered to deliver powerful, thorough cleaning with optimal efficiency. Designed with a three-compartment washing system, this washer easily manages high volumes, ensuring that each crate meets rigorous hygiene standards. The double-track setup supports continuous throughput, making it ideal for large-scale operations that demand reliable, efficient cleaning.

Achieve impeccable washing and drying results every time with SS Engineers’ Incline Crate Washer. Built for durability and consistent performance, this washer guarantees top-quality cleaning that supports productivity without compromising cleanliness.

SS Engineers specializes in designing and manufacturing Industrial Components Washers for stainless steel and aluminum products, featuring pre-wash, detergent wash, hot water rinse, air blowing, hot air drying, and air cooling. Each stage is engineered to ensure thorough and efficient cleaning.

Built for companies of all sizes, SS Engineers’ Industrial Components Washers deliver powerful, durable performance that enhances productivity. Our washers are crafted to meet the demands of mass, medium, and small-scale operations, providing exceptional cleaning results and reliability.

Perform regular maintenance on your LPG Cylinder Washer to ensure peak performance and extend equipment life. Key steps include cleaning or replacing filters, inspecting and cleaning nozzles, monitoring water pressure, and checking detergent levels. Descaling may also be required to prevent buildup and maintain efficient operation.

Routine care of the LPG Cylinder Washer optimizes its cleaning power and minimizes downtime. Consistent maintenance keeps the washer running smoothly, ensuring it meets productivity demands while maintaining high standards of cleanliness and safety.

Optimize large-scale cleaning operations with SS Engineers' advanced Pallet Washer systems, designed for high-efficiency cleaning across all types and sizes of pallets. Regardless of the type of pallet you use, our washers provide a tailored cleaning solution to meet your needs, ensuring thorough sanitation and superior performance.

Our expertise extends beyond pallets; we specialize in crate, container, and conveyor washers, tackling various items like jelly cans, plates, lids, molds, barrels, and buckets. With years of innovation in industrial washing systems, we offer solutions for cleaning large quantities efficiently. Trust SS Engineers to elevate your operations with reliable and effective Pallet Washers that meet the highest industry standards.

Experience the advanced cleaning power of SS Engineers Steam Washer, designed to efficiently remove excess oil, grease, wax, and other non-water soluble particles from carriers and containers. Ideal for environments where water-based systems are not feasible, our Steam Washing System delivers exceptional results, ensuring surfaces are thoroughly cleaned without the use of water.

Utilize our Steam Washer to prepare surfaces for various finishing processes by effectively degreasing and eliminating oxidation and water spots. This innovative solution enhances the cleanliness and readiness of parts for further processing, offering a reliable alternative in industrial applications. Trust SS Engineers for high-quality, efficient steam cleaning systems that meet your specific cleaning needs.

Optimize cooling with SS Engineers' Tin Cooling Conveyor, designed to reduce heat through a controlled water sprinkling system as products move along the line. Spanning 6 to 8.5 meters, this conveyor provides efficient cooling for all tin products, ensuring quality and preserving integrity.

Featuring modular 2.5-meter sections, the Tin Cooling Conveyor is customizable for various production needs. Equipped with precision sprinklers, it maintains consistent cooling across the line, enhancing efficiency and meeting industrial demands.

Unlock the power of SS Engineers’ advanced Tray Washer solutions by reaching out for a tailored quotation. Our state-of-the-art washing systems are designed to efficiently clean everything, from transportation and packing crates to production line crates and utensils, ensuring optimal performance across a range of applications.

Transform your material handling process with SS Engineers’ customizable solutions. Our Tray Washer systems seamlessly integrate into your workflow, enhancing operational efficiency and addressing the unique cleaning needs of your industry. Contact us today to get started!

Elevate your cleaning process with SS Engineers & Consultants’ high-efficiency Utensil Washer. Engineered to handle polished cookware, stainless steel, and aluminum pots, our washers boost production capacity and streamline workflows for businesses of any size.

Achieve spotless, quick results by integrating our Utensil Washer into your line. Contact us to explore customized solutions that enhance efficiency and meet your specific production needs.